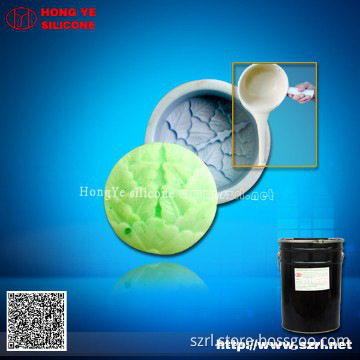

Molds Making Liquid Silicone Rubber Mould Making,silicon manufacturer

Your message must be between 20 to 2000 characters

Contact NowBasic Specification

| color | white |

|---|---|

| Application | silicon technology for mold making serious |

| appearance | liquid material |

| hs code | 39100000 |

| operation way | by brushing or pouring |

| Eco-Friendly | Yes |

| Test Report | SGS |

Detail Description

Specifications of silicon technology for mold making serious

silicon technology for mold making serious

1,good operability

2,easy to demold

3,good tensile,low shrinkage.

4,high duplication

silicon technology for mold making serious

RTV-2 condensation cure silicone rubber ( RTV-2 silicone )

RTV-2 condensation cure silicone rubber is a common silicone rubber that can get cured at the room temperature.The raw material of the silicone is Polydimethylsiloxane (-(-O-Si(CH3)2-)-),which is at the both ends of –OH.The chemical formula is as below:

CH3 CH3 CH3

Ho—si—o Si o Si OH

CH3 CH3 n CH3

Different models of RTV silicone will be produced by adding different kinds and amounts of extender and other additives into the unvulcanized rubber. It is composed as two parts, one is the unvulcanized silicone, and the other is the curing agent, cross-linker and the other curing agent.

Performance of silicon technology for mold making serious :

Vulcanized curing silicone is with the good features of excellent insulation resistance, voltaic arc resistance, high corona resistance ,water-tolerant, ozone proof, aging resistance, high and low temperature stability, and it could be used under the temperature of -60~200°C.

After adding the curing agent and cross-linker into the unvulcanized silicone, pls go for the vacuum pumping process if necessary.Then the mixture will be cured into the elstomer. And the pot life and the curing time can be changed by controling the formula and the volume of the catalyst.

silicon technology for mold making serious silicon technology for mold making serious

silicon technology for mold making serious silicon technology for mold making serious

Main applications of silicon technology for mold making serious :

The mixing ratio of the two parts of RTV-2 is adjustable. One kind of mixing ratio can get many kinds of cured product with different specification and performance. What’s more, by adding special additives, it can get deeper layer \'curing and increase the corrosion resistance.Thus it is used widely for insulating, sealing, bonding, filleting, dampproofing, shockproofing and as the raw material for the silicone roller, which could be applyied to the field of electronicals, autocar, aviation industry, machanical construction, textile industry, chemical industry, printing and light industry, hygienism industry and so on. Besides, because of the easy-releasing ability, RTV-2 silicone, as the soft mould material, also could be mainly applied for making molds for replicating stationaries, cafts, toys, artificial leather, electronicals, instruments, machine parts and so on.

Different products with different performance for different applications by different technics could be provided by our company.

silicon technology for mold making serious silicon technology for mold making serious

Need any help on silicone rubber, please feel free to contact Ms Maggie:

Tel:86-755-89212369

Mob:86-13828847574

e-mail: hyju(at)szrl(dot)net

Skype:maggie.cao82

Additional Information

| Payment Terms | T/T, Western Union |

|---|---|

| Minimum Order | 200 |

| Lead Time / Delivery Time | 5 Day(s) |

| Sample Available | NO |

| Delivery Details | Packaging & Delivery Packaging Detail: 25kg/drum and 200kg/drum Delivery Detail: within 3 days after payment confirmed in our bank |

| FOB Port | Shenzhen |

| Loading Info | Packaging & Delivery Packaging Detail: 25kg/drum and 200kg/drum Delivery Detail: within 3 days after payment confirmed in our bank |

| Packing Info | Packaging Detail: 25kg/drum and 200kg/drum |

| Target Market(s) | Eastern Europe, Africa(except Middle East), Japan & Korea, Mainland China |

Related Keywords