RTV-2 silicone for GRC molding

Your message must be between 20 to 2000 characters

Contact NowBasic Specification

| operation way | by brushing or pouring |

|---|---|

| application | RTV-2 silicone for GRC molding |

| appearance | liquid material |

| hs code | 39100000 |

| port | shenzhen |

| Test Report | Other |

| Eco-Friendly | Yes |

Detail Description

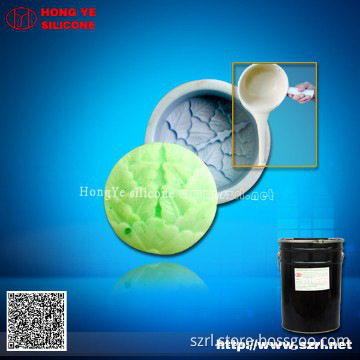

RTV-2 silicone for GRC molding

Supply new RTV 2 silicone for concrete mold making:

New RTV 2 silicone for concrete mold making are used for mold duplication and delicate mold making for concrete mold making, poli crafts,resin crafts lighting and candle crafts

Operation of new RTV 2 silicone for concrete mold making:

1,Take 100g of part A and add 2g of part B and mix the silicone rubber and curing agent evenly.

2, vacuum-pumping the mixture of silicone rubber and curing agent, this step must takes less than 10 minutes

3, Evenly brush the mixed silicon rubber on the product which is covered with mold spray with a brush or a brush pen.

4, Cover a glass cloth on it after 30 minutes of a cross linking reaction, which can increase the tension and tear strength of the mold.

New RTV 2 silicone for concrete mold making Features:

A. a low cost way to make moulds

B. a mould is built using a layer process

C. more time and fairly lengthy process to make your mould

D. easy to use

E. amazing elongation to break

Datasheet

RTV-2 silicone for GRC molding RTV-2 silicone for GRC molding RTV-2 silicone for GRC molding

| Model | HongYe RTV 628# |

| Appearance | White |

| Mixing Ratio (%) | 20:1 |

| Operating time (mins 25 0C ) | 40~50 |

| Curing time(hours 25 0C) | 3~6 |

| Hardness (A°) | 28±2 |

| Viscosity (Mpas -25 0C) | 22000±1000 |

| Tensile-strength(kgf /cm² ) | 42±2 |

| Tear-strength (kgf /cm ) | 26±2 |

| Elongation-break(%) | ≥ 450 |

| Linear shrinkage(%) | 0.01~0.03 |

RTV-2 silicone for GRC molding RTV-2 silicone for GRC molding RTV-2 silicone for GRC molding

Frequently asked questions of New RTV 2 silicone for concrete mold making

1. Why should the silicone mold be reused only for a few times? It can be due to the following reasons: a. Adding too much silicone oil in to silicon rubber. Silicon oil is an additive which destroies the molecular weight of silicone rubber and reduce the tension and tear strength. b. Using the silicon rubber with a high hardness to make molds for small sized products with delicate and intricate designs and the silicon rubber with a low hardness to makes molds for large sized products with simple designs.

(Notes: we should choose the silicon rubber specifically according to the requirements of our products to avoid this problem.)

RTV-2 silicone for GRC molding RTV-2 silicone for GRC molding RTV-2 silicone for GRC molding

Need any help on silicone rubber, please feel free to contact Ms Crystal:

Tel:86-755-89212369

Mob:86-18938867509

E-mail: hyxd(at)szrl(dot)net

Skype:shisi1991

Additional Information

| Payment Terms | L/C, T/T |

|---|---|

| Minimum Order | 200kg |

| Lead Time / Delivery Time | 3 Day(s) |

| Sample Available | YES |

| Delivery Details | deliver Within 3 days after getting your bank receipt |

| FOB Port | Shenzhen |

| Loading Info | by ship or air |

| Packing Info | 20kg/drum,200/drum RTV-2 silicone for GRC molding |

| Target Market(s) | North America, Oceania, Southeast Asia, Eastern Europe, Africa(except Middle East), Hong Kong/ Macao/ Taiwan, Latin America, Japan & Korea, Middle East & South Asia, Mainland China, Western & Southern Europe, Northern Europe, Central & Southern Asia, Middle East |

Related Keywords