silicone rubber for GRC Molding

Your message must be between 20 to 2000 characters

Contact NowBasic Specification

| hs code | 39100000 |

|---|---|

| color | white,green,red,yellow,blue |

| appearance | liquid material |

| application | Molding silicone rubber for GRC |

| validity | 1year |

| Eco-Friendly | Yes |

| Test Report | SGS |

Detail Description

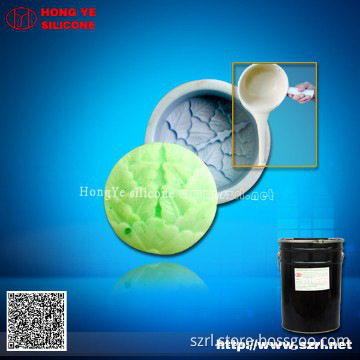

RTV 2 molding silicon rubber HY630 for resin&plaster crafts molds making

Applications of RTV 2 molding silicon rubber:

RTV 2 molding silicon rubber is mainly applied for making various molds,such as reproduction of concrete or cement , poly resin, epoxy, polyurethane-polymer, plaster, gypsum, soaps, candle & lighting, architecture, decorative arts and crafts, plastic toy, gift and stationery, big statue, cultural relic product, etc..

RTV 2 molding silicon rubber HY630:

Model |

RTV-630 |

Appearance |

white |

Mixing proportion of curing agent(%) |

2% |

Operating time ( mins ) |

30 |

Curing time( hours ) |

5--6 |

Hardness (A°) |

30 |

Density ( g/cm3) |

1.06 |

Viscosity (CS) |

23000 |

Tensile-strength ( kgf /cm2) |

37 |

Tear-strength (kgf /cm2) |

25 |

Elongation-break(%) |

510 |

Retractility(%) |

0.3 |

Features of RTV 2 molding silicon rubber:

1. Two-part of RTV 2 molding silicon rubber: flowable liquid silicon and curing agent.

2. RTV 2 molding silicon rubber Cures at room temperature within 5-46hours.

3. RTV 2 molding silicon rubber has An exceptional fluidity and good operability.

4. RTV 2 molding silicon rubber has good Temperature and deformation resistance as well as low shrinkage.

5. RTV 2 molding silicon rubber has High duplication times.

Operations for RTV 2 molding silicon rubber:

Step One to use RTV 2 molding silicon rubber:Take 100g of part A and add 2g of part B and mix the silicon rubber and the curing agent evenly.

Step Two to use RTV 2 molding silicon rubber: vacuum pumping

Without exception, this takes less than 10 minutes. Otherwise, it will cause cross linking reaction, and no more further steps will be available.

Step Three to use RTV 2 molding silicon rubber: Brushing cast & Perfusion Molding operation.

(3) Brushing cast or Perfusion Molding operation

a.Carefully wash the original mold , then dry it with an air gun. Then brush some release agent such as soap water, detergent,vaseline,liquid wax ,etc..

b Evenly brush the mixed silicon rubber on the product which is covered with mold spray with a brush or a brush pen.

c. After the cross linking reaction (about 30 minutes), brush a second coat which can increase the tension and tear strength of the mold.

d. Cover a glass cloth on it after another 30 minutes of a second cross linking reaction, and use a brush pen or a brush to avoid any interstices.

e. Cover a third coat.

(Note: if you have high requirements for the tension and the tear strength for the mold, please repeat step c and step d. Hence, the finished silicone moulds will have a good quality and a longer life, which can help you save cost and increase production efficiency.)

(4)Operations for the external mold:

a. Make a square frame with four pieces of wooden boards or rubber plates, then place the product which is covered with the finished silicon rubber mould in the middle.

b. Slowly and evenly perfuse the gypsum into the square frame. Also you can brush the resin on the product which is covered with the finished silicon rubber mould with a brush or a brush pen. Repeat this process two or three time after the cross link reaction.

(5) Pouring moulding:

It is suitable for simple products with the smooth surface. Without any mold lines, which helps you save time and is easy for operation. Evenly and slowly perfuse the mixed silicone rubber into the square fram. After the cross linking reaction and the silicone rubber turns dry,you can take the products out. Thus, the mold has been done.

(Note:we usaully use soft silicone rubber to make molds by perfusing, which is easy for demoulding and will not damage the product in the silicone molds.)

Packaging, storage and transportation on RTV 2 molding silicon rubber compound

(1) The RTV-2 silicone rubber is packed with vacuumed thick PE bag inside,and iron barrel (tin) outside, packing in 5 kg, 25 kg , 200 kg.

Curing agent (catalyst, cross-linking agent or other additives) are packed with 1 kg, 25 kg plastic bottles or barrels . and the weight is 3-5% of total silicone.

(2) The product should be stored in a cool dry place, avoid the sun and rain, avoid to touch with acids, alkalis, salts and other compounds. The shelf life is one year from the date of production. For some models , after three months, the viscosity will increase, generally no effect for the normal use. If over the storage period, through the re-examination,it can still be used. Curing agent goes bad easily by absorbing moisture in the air and the quality will get effected, so it should be sealed for storage.

(3) The goods is NOT subject to IMDG except the curing agent.

Need any help on silicone rubber, please feel free to contact Ms Nancy:

Mob: 86-18938867585

Tel: 86-755-89948019

Skype: nancy19870715

MSN: nancy870715( at ) hotmail( dot)com

Email: hyr (at) dzrl ( dot ) net

Additional Information

| Payment Terms | L/C, T/T, Western Union |

|---|---|

| Minimum Order | 200kg |

| Lead Time / Delivery Time | 6 Day(s) |

| Sample Available | YES |

| Delivery Details | within 3 days after getting paymentby air and by shippment |

| FOB Port | Shenzhen |

| Loading Info | within 3 days after getting paymentby air and by shippment |

| Packing Info | within 3 days after getting paymentby air and by shippment |

| Target Market(s) | North America, Oceania, Southeast Asia, Eastern Europe, Africa(except Middle East), Latin America, Japan & Korea, Middle East & South Asia, Mainland China, Western & Southern Europe, Northern Europe, Central & Southern Asia, Middle East |

Related Keywords