Moulding Silicone Rubber for Casting

Your message must be between 20 to 2000 characters

Contact NowBasic Specification

| appearance | liquid material |

|---|---|

| Color | Any color is available |

| application | Molding Silicone Rubber for Casting |

| Certificate | ISO9001,SGS,RHOS, REACH |

| hs code | 3910000 |

| Eco-Friendly | Yes |

| Test Report | SGS |

Detail Description

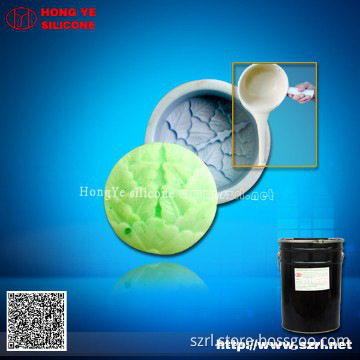

Molding Silicone Rubber for Casting

mainly used for toy gifts and craftwork gifts with the advantages of good tensile strength, high tear strength, high temperature resistance, high duplication times and repeated use, etc. It is suitable for small products or fine and precision products which is difficult to demould. This silicone rubber is one of the products with the highest use level in the production of craftwork gifts and the shrinkage is up to 2‰.

Molding Silicone Rubber for Casting Applications

Molding Silicone Rubber for Casting( 638#) is good for Poly technique, lightings, candles, and molds in multiple pieces for large products.

Molding Silicone Rubber for Casting Standard Datasheet

Model |

Appearance |

Viscosity (cs) |

Hardness (Ao) |

Tensile Strength (kn/m) |

Tear Strength (kn/m) |

Elongation (%) |

Mixing ratio(%) |

Operating Time(H) |

Curing Time(H) |

638 |

White |

30000~38000 |

36±2 |

≥3.8 |

≥2.8 |

≥380 |

2~3 |

0.5~1 |

2~5 |

The proportions and reactions of the Molding Silicone Rubber for Casting curing agent and the silicon are listed as follows

1. Adding curing agent 1%, the silicone can still be operated within 2.5 hours and can be demoulded after 6-8 hours.

2. Adding curing agent 2%, the silicone can still be operated within 50 minutes to 1 hour and can be demoulded after 2-3 hours.

3. Adding curing agent 3%, the silicone can still be operated within 28 - 30 minutes and can be demoulded after 1.5-2 hours.

4. Adding curing agent 4%, the silicone can still be operated within 10 - 15 minutes and can be demoulded after 1 -1.5 hours.

Mob:86-18938867575

Email :hyjw(at)szrl(dot)com

Welcome to our website www(dot)szrl(dot)net

Additional Information

| Payment Terms | L/C, T/T, Western Union |

|---|---|

| Minimum Order | 100kgs |

| Lead Time / Delivery Time | 3 Day(s) |

| Sample Available | YES |

| Delivery Details | By sea |

| FOB Port | Shenzhen |

| Loading Info | FOB, CNF or CIF |

| Packing Info | 5kg/drum, 20kg/drum, 25 kg/drum, 200kg/drum Molding Silicone Rubber for Casting |

| Target Market(s) | North America, Oceania, Southeast Asia, Eastern Europe, Africa(except Middle East), Hong Kong/ Macao/ Taiwan, Latin America, Japan & Korea, Mainland China, Western & Southern Europe, Northern Europe, Central & Southern Asia, Middle East |

Related Keywords