molds making silicone of artificial stone mold,rtv silicone,silicon

Your message must be between 20 to 2000 characters

Contact NowBasic Specification

| color | any |

|---|---|

| MOQ | 200kg |

| curing agent | 4% for free charged |

| Application | Molding silicone rubber for artificial stone mold |

| sticker | available |

| Eco-Friendly | Yes |

| Test Report | SGS |

Detail Description

Molding silicone rubber for artificial stone mold making

1.Molding silicone rubber for artificial stone mold making - application:

Molding silicone rubber for artificial stone mold making is primarily intended for mold making of gypsum, concrete, poly resin ,PU resin, unsaturated resin crafts, lighting and candles crafts , plastic toys , stationery gifts crafts industry, large statue, Buddha, relievo furniture, furniture decorative materials, statues Buddha, artifacts copied, building decoration materials, large-scale cement mold, artificial fossils Factory, European buildings, simulation landscapes, animals and plants sculpture, sandstone crafts and so on.

2. Molding silicone rubber for artificial stone mold making - feature:

1). Good characteristics of easy-operation

2). Light viscosity and good flowability

3). Low shrinkage

4). Excellent tensile and tear strength

5). Favorable hardness

6). High temperature resistance, acid and alkali-resistance and ageing resistance

7). High duplication times

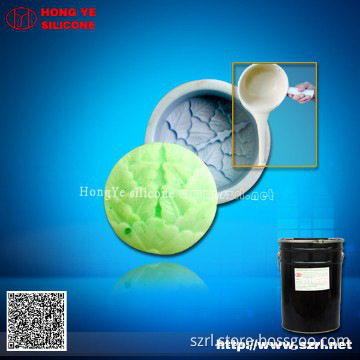

3. Molding silicone rubber for artificial stone mold making - picture show:

4. Molding silicone rubber for artificial stone mold making - datasheet:

Model |

Appearance |

Viscosity (cs) |

Hardness (Ao) |

Tensile Strength (kgf/c) |

Tear Strength (kgf/) |

Elongation (%) |

Mixing ratio(%) |

Operating Time(H) |

Curing Time(H) |

628 |

White |

14000~16000 |

25~28 |

≥35 |

≥25 |

≥500 |

2~3 |

0.5 |

2~4 |

Model |

Appearance |

Viscosity (cs) |

Hardness (Ao) |

Tensile Strength (kgf/c) |

Tear Strength (kgf/) |

Elongation (%) |

Mixing ratio(%) |

Operating Time(H) |

Curing Time(H) |

728 |

White, red |

15000~17000 |

26~28 |

≥35 |

≥22 |

≥470 |

2~3 |

0.5 |

2~4 |

5. Molding silicone rubber for artificial stone mold making - operation:

If the customer wants to make large products and large size molds, the mold should be made of silicon rubber with high hardness. On the contrary, if the mold with fine and precision patterns, it should be made of silicon with low hardness. The amount of the curing agent depends on the actual requirements of the customer. If molds requiring fast drying and demold, more curing agent is needed; contrarily, if molds requiring slower drying and demold, less curing agent is needed.

(Note: our company does not recommend you to add silicone oil. If a special soft silicone mold or fine detailed and complex patterns products are required, 5%-10% silicone oil can be added to soften the mold for easy demold.)

6. Molding silicone rubber for artificial stone mold making - FAQ:

Why does the silicone mold get burnt out?

This consequence happens only because you have left out the important notes when using unsaturated resin materials to produce your products. The unsaturated resin produces great heat when added the curing agent. So you must demould the product within 3 minutes to avoid this problem.

7. Molding silicone rubber for artificial stone mold making - certification:

ISO9001: HK05/01358

SGS:GZ0606100461/CHEM

RoHS:BTRS091718751

Patent:ZL200520001597.8

Additional Information

| Payment Terms | L/C, T/T, Western Union, Others |

|---|---|

| Minimum Order | 200kg |

| Lead Time / Delivery Time | 3 Day(s) |

| Sample Available | YES |

| Delivery Details | within 3 days after getting payment |

| FOB Port | Shenzhen |

| Loading Info | By ship or air |

| Packing Info | 25kg/drum and 200kg/drum |

| Target Market(s) | North America, Oceania, Southeast Asia, Eastern Europe, Africa(except Middle East), Hong Kong/ Macao/ Taiwan, Latin America, Japan & Korea, Middle East & South Asia, Mainland China, Western & Southern Europe, Northern Europe, Central & Southern Asia, Middle East |

Related Keywords