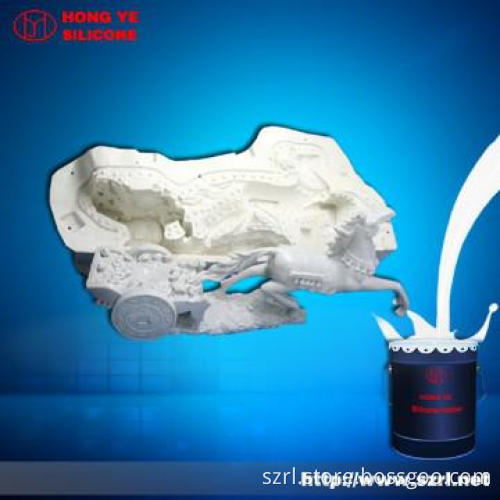

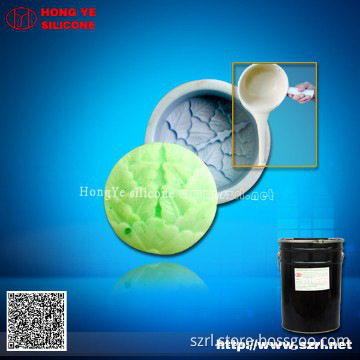

RTV Molding Silicone Rubber,silicone moulds

Your message must be between 20 to 2000 characters

Contact NowBasic Specification

| appearance | liquid silicone |

|---|---|

| Certifications | RoHS.MSDS.SGS |

| Delivery Time | within 3 days after payment confirmed in our bank |

| Supply Ability | 8 Ton per Day |

| application | RTV Molding Silicone Rubber with any color |

| Eco-Friendly | Yes |

| Test Report | SGS |

Detail Description

Application of Molding Silicone Rubber with any color

Molding Silicone Rubber with any color with favorable hardness, is specially suitable for large crafts mould making and duplication of poly resin crafts in pouring or brushing way, PU crafts, gypsum or plaster, unsaturated resin, lighting and candles crafts, plastic toy, stationery gifts crafts, large statue buddha, furniture decoration, cement, articficial stone, etc.

Advantages of molding silicone rubber with any color : light viscosity, pourable effort, good fluidity, easy-operation, good tension and high tear strength.

Characteristics of Molding Silicone Rubber with any color

| Model | 630# |

| Appearance | white |

| Mixing proportion of curing agent (%) | 3% |

| Operating time (mins 25 0C ) | 30-45 |

| Curing time(hours 25 0C) | 6-8 |

| Hardness (A°) | 30±2 |

| Density ( g/cm 3 ) | 1.08 |

| Viscosity (mPas -25 0C) | 18000±2000 |

| Tensile-strength(kgf /cm2 ) | ≥43 |

| Tear-strength (kgf /cm ) | ≥29 |

| Elongation-break(%) | ≥430 |

| Application(most for resin, gypsum and cement product to make moulds) | Most suitable for medium and large sized product by brushing method |

Brief features of Molding Silicone Rubber with any color :

1. resistance to deformation, high-temperature

2. high reproduction times

3. good tensile strength

4. exceptional fluidity and good operability.

Operation Instruction for Molding Silicone Rubber with any color :

Step One:Take 100g of part A and add 2g of part B and mix the silicone rubber and curing agent evenly.

Notes: Moulding silicon rubber is a kind of flowing liquid and it contains two parts. Part A is a kind of white flowing liquid and part B is the curing agent. Remember to mix part A and part B evenly, otherwise the silicon rubber will be partly solidified and this will give birth to difficulties in your final operation. What’s more, the finished moulds will meet a short life. All of these will cause a waste of silicon rubber.

Step Two: vacuum pumping

Without exception, this step takes less than 10 minutes. Otherwise, it will cause cross linking reaction, and no more further steps will be available.

Step Three: Brushing cast & Perfusion Molding operation

Brushing cast:

a. Evenly brush the mixed silicon rubber on the product which is covered with mold spray with a brush or a brush pen.

b. After the cross linking reaction (about 30 minutes), brush a second coat which can increase the tension and tear strength of the mold.

c. Cover a glass cloth on it after another 30 minutes of a second cross linking reaction, and use a brush pen or a brush to avoid any interstices.

d. Cover a third coat.

(Note: if you have high requirements for the tension and the tear strength for the mold, please repeat step c and step d. Hence, the finished silicone moulds will have a good quality and a longer life, which can help you save cost and increase production efficiency.)

Perfusion moulding:

It is suitable for simple products with the smooth surface.Without any mold lines,which helps you save time and is easy for operation.Evenly and slowly perfuse the mixed silicone rubber into the square fram.After the cross linking reaction and the silicone rubber turns dry,you can take the products out.Thus,the mold has been done.

(Note:we usaully use soft silicone rubber to make molds by perfusing,which is easy for demoulding and will not damage the product in the silicone molds.)

Operations of external mold:

a. Make a square frame with four pieces of wooden boards or rubber plates, then place the product which is covered with the finished silicon rubber mould in the middle.

b. Slowly and evenly perfuse the gypsum into the square frame. Also you can brush the resin on the product which is covered with the finished silicon rubber mould with a brush or a brush pen. Repeat this process two or three time after the cross link reaction.

FAQ of Molding Silicone Rubber with any color

Why is the silicone rubber mold oily?

Basically, molding silicone rubber doesn\'t contain any oil, so it won\'t be oily. The reasons for the oily molds can be deducted from the below 3 factors:

1. Added white oil, which is the compound of silicone oil and white oil. The white oil is not silicone oil but a kink of petrochemicals;

2. Added too much silicone oil. Normally, we donot advise our customers to add any silicone oil into silicone rubber. If necessary, the ratio must be 5%-10%;

3. Added too much curing agent, this is another reason for oily mold.

Tips:

1. weigh the liquid silicone rubber and curing agent exatly .

2. Stir the liquid silicone rubber and curing agent evenly .

3.we shouldchoose the right hardness to making diffirent size of product mold.

Need any help on silicone rubber, please feel free to contact Ms Maggie:

Tel:86-755-89212369

Mob:86-13828847574

E-mail: maggie822014(at)gmail(dot)com

Skype:maggie.cao82

Additional Information

| Payment Terms | L/C, T/T, Credit Card, Western Union, Others |

|---|---|

| Minimum Order | 200 |

| Lead Time / Delivery Time | 5 Day(s) |

| Sample Available | YES |

| Delivery Details | Delivery Time:within 5 days after payment confirmed in our bank. |

| FOB Port | Shenzhen |

| Loading Info | 20kg/drum,200/drum |

| Packing Info | Packaging Details:25kg/drum and 200kg/drum |

| Target Market(s) | North America, Oceania, Southeast Asia, Eastern Europe, Africa(except Middle East), Hong Kong/ Macao/ Taiwan, Latin America, Japan & Korea, Middle East & South Asia, Mainland China, Western & Southern Europe, Northern Europe, Central & Southern Asia, Middle East |

Related Keywords