Rtv-2 Silicone Rubber For Gypsum Mold Making

Your message must be between 20 to 2000 characters

Contact NowBasic Specification

| Color | White |

|---|---|

| Brand Name | HY silicone rubber |

| Model Number | HY 6 series |

| mix Ratio with agent | 100:4 |

| Application | Mold Making |

| Eco-Friendly | Yes |

| Test Report | SGS |

Detail Description

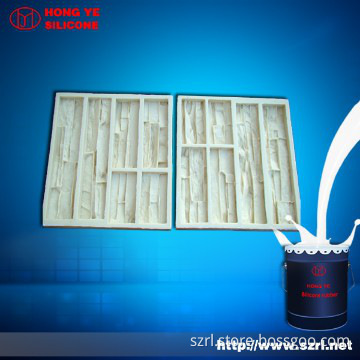

Description of Rtv-2 Silicone Rubber For Gypsum Mold Making

HY630# Silicone rubber is kind of condensation mold making silicone rubber. It’s generally named two-components silicone rubber which will be cured under room temperature, Part A is a flowable liquid, part B is the curing agent. It features an exceptional fluidity and good operability.

Application of Rtv-2 Silicone Rubber For Gypsum Mold Making

Our silicone rubber is perfect molding material and casting material, it can used to make molds for the products which are made from below materials: concrete stone, cement, gypsum, plaster, fiberglass, polyester, resin, polyresin, polyurethane, bronze, wax, crystal, candle, and so on

HY630# Silicone rubber is mainly suitable for middle sized product with some pattern by pouring operation, additive is available for brushing operation

Technical Parameters —— Rtv-2 Silicone Rubber For Gypsum Mold Making

| Model | 630# |

| Hardness | 30±2 |

| Appearance | white |

| Mixing proportion of curing agent (%) | 4% |

| Operating time (mins 25 0C ) | 30-45 |

| Curing time(hours 25 0C) | 3-4 |

| Density ( g/cm 3) | 1.08 |

| Viscosity (mPas -25 0C) | 27000±20000 |

| Tensile-strength(kgf /cm2 ) | ≥47 |

| Tear-strength (kgf /cm) | ≥38 |

| Elongation-break(%) | ≥ 450 |

Using instructions

Step 1: prepare the original molds

You must make sure your original molds perfect. fix it on a board. And fix the original mold on a board , then used four piece of board to enclose the original molds .

Step 2: Take 100 parts A and add 3 parts B and mix the silicone rubber and curing agent evenly.

*Notes: Molding silicon rubber is a kind of flowing liquid and it contains two parts. Part A is a kind of flowing liquid and part B is the curing agent. Remember to mix part A and part B evenly, otherwise the silicon rubber will be partly solidified and this will give birth to difficulties in your final operation. What’s more, the finished molds will meet a short life. All of these will cause a waste of silicon rubber.

Step 3: Vacuum pumping

Without exception, this step takes less than 10 minutes. Otherwise, it will cause , and no more further steps will be available.

Step 4: Pouring cast or brushing cast

*Notes: We usaully use soft silicone rubber to make molds by pouring molding, which is easy for demoulding and will not damage the product in the silicone molds.)

Package for Rtv-2 Silicone Rubber For Gypsum Mold Making

25Kgs/drum vacuum packing,200Kgs/drum vacuum packing.

Shelf life and transportation

1. Twelve(12) months when stored at 25C in tightly closed original packages.

2. This kind of product is non-dangerous product, which could be transported as general chemicals.

For more information , pls feel free to contact Ms omiga

Mob:86-18938867575

Email :hyjw(at)szrl(dot)com

Welcome to our website www(dot)szrl(dot)net

Additional Information

| Payment Terms | L/C, T/T, Western Union, Paypal, Others |

|---|---|

| Minimum Order | 200 kgs |

| Lead Time / Delivery Time | 5 Day(s) |

| Sample Available | YES |

| Delivery Details | Delivery Time: Within 5 days after we obtain your bank receipt. |

| FOB Port | Shenzhen, |

| Loading Info | You can choose shipping way by ship or by air |

| Packing Info | 25kgs/ drum, 200kgs/ drum |

| Target Market(s) | North America, Oceania, Southeast Asia, Eastern Europe, Africa(except Middle East), Hong Kong/ Macao/ Taiwan, Latin America, Japan & Korea, Middle East & South Asia, Mainland China, Western & Southern Europe, Northern Europe, Central & Southern Asia, Middle East |

Related Keywords