RTV-2 silicone rubber for molding

Your message must be between 20 to 2000 characters

Contact NowBasic Specification

| application | silicone rubber for food grade molds |

|---|---|

| color | any |

| appearance | liquid material |

| hs code | 39100000 |

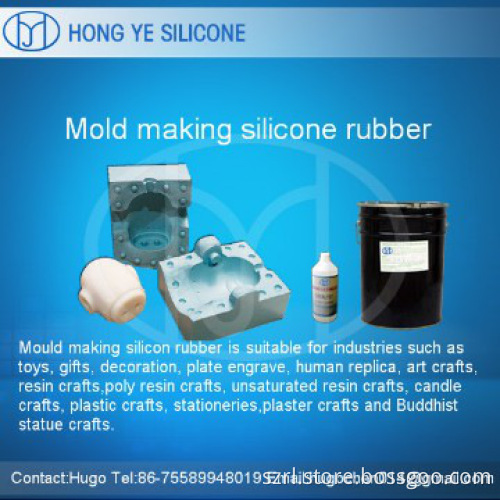

| operation way | by brushing or pouring |

| Eco-Friendly | Yes |

| Test Report | SGS |

Detail Description

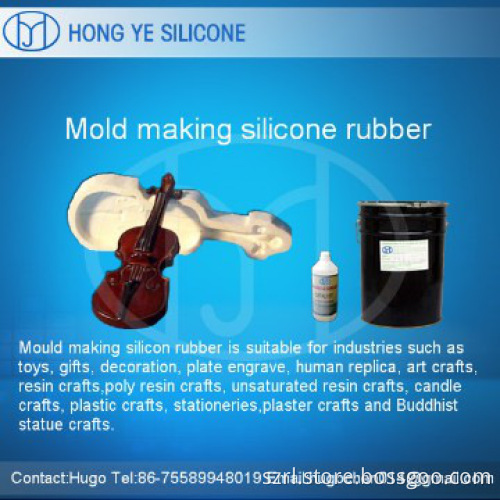

Application of RTV-2 silicone rubber for molding

1. RTV-2 Silicone Rubber for molding can used for poly resin crafts, PU crafts, PU resin crafts ,gypsum crafts ,unsaturated resin crafts, lighting and candles crafts ,plastic toy , stationery gifts crafts industry,

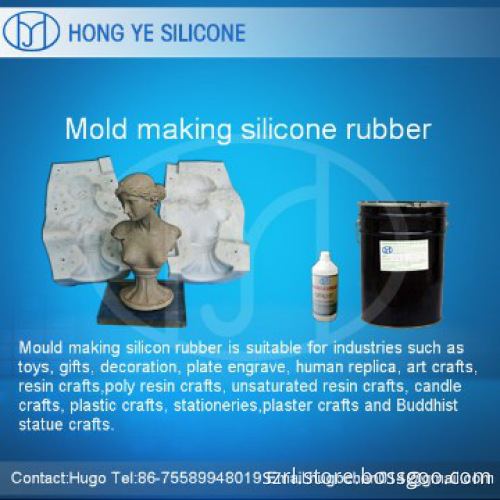

2. RTV-2 Silicone Rubber for molding is applicable for large statue Buddha, relievo furniture, furniture decorative materials, statues Buddha, artifacts copied, building decoration materials, large-scale cement mold,

3. RTV-2 Silicone Rubber for molding is intend for artificial fossils Factory, Europe component factory, simulation landscapes, animals and plants sculpture, sandstone crafts and so on.

Features of RTV-2 silicone rubber for molding

1 Two part of liquid fluid: liquid white silicone and curing agent.

2 Cure at room-temperature within 4-8 hours, but all performance will act perfectly when it cure within 24 hours.

3 Good fluidity and excellent operation.

4 Good resistance to weather, temperature, aging, acid..

5 Excellent tear strength, comfortable duplication times.

1. Why could the RTV-2 silicone rubber for molding be reused only for a few times?

It can be due to the following reasons:

a. Adding too much silicone oil in to silicon rubber. Silicon oil is an additive which destroies the molecular weight of silicone rubber and reduce the tension and tear strength.

b. Using the silicon rubber with a high hardness to make molds for small sized products with delicate and intricate designs and the silicon rubber with a low hardness to makes molds for large sized products with simple designs.

(Notes: we should choose the silicon rubber specifically according to the requirements of our products to avoid this problem.)

2. Why does theRTV-2 silicone rubber for molding get burnt out?

This consequence happens only because you have left out the important notes when using unsaturated resin materials to produce your products. The unsaturated resin produces great heat when added the curing agent. So you must demould the product within 3 minutes to avoid this problem.

3. Why does the RTV-2 silicone rubber for molding appear to be dry outside but wet inside?

Because rtv-2 silicone rubber for molding is a kind of condensation silicone rubber, which get solidified after absorbing moisture from the air. In order to provide a significant shelf-life for the silicon rubber, we will dry out the water in the silicon rubber.

Solution: Add 0.05% water into the silicon rubber and Stir over a low speed briefly when you use it.

4. Why is the tear strength of the silicone mold weak?

In order to reduce the viscosity of silicone rubber and pursue a good quality, you may add a lot of silicone oil into the silicon rubber when making molds. In fact, it might have just the opposite effect. The tension and the tear strength will be reduced badly with the addition of silicon oil. And the silicon molds will be in a weak and flimsy manner.

During operate ofRTV-2 silicone rubber for moldingthe three impotant thing to pay attention :

1. weigh theliquid silicone rubber and curing agent exatly .

2. Stir theliquid silcone rubber and curing agent evenly .

3.we shouldchoose the right hardness to making diffirent size of product mold.

Need any help on silicone rubber, please feel free to contact Hugo:

TEL:086-755-89948019

FAX:086-755-89948030

MOBILE:086-13428680288

SKYPE: hugo.chen007

Website:www(dot)szrl(dot)net

E-MAIL:hugochen014(at)gmail(dot)com

Additional Information

| Payment Terms | L/C, T/T, Western Union |

|---|---|

| Minimum Order | 200kh |

| Lead Time / Delivery Time | 5 Day(s) |

| Sample Available | NO |

| Delivery Details | within three days after getting your payment |

| FOB Port | Shenzhen |

| Loading Info | FOB Shenzhen port by sea |

| Packing Info | 20kg and 200kg per drum Silicone Rubber for Food Grade Molds |

| Target Market(s) | North America, Oceania, Southeast Asia, Eastern Europe, Africa(except Middle East), Hong Kong/ Macao/ Taiwan, Latin America, Japan & Korea, Middle East & South Asia, Mainland China, Western & Southern Europe, Northern Europe, Central & Southern Asia, Middle East |

Related Keywords