High Temperature Silicone for Jewelry Casting

Your message must be between 20 to 2000 characters

Contact NowBasic Specification

| hs code | 39100000 |

|---|---|

| Delivery Time | within 3 days after payment confirmed in our bank |

| application | High Temperature Silicone for Jewelry Casting |

| Certifications | RoHS. MSDS.SGS ISO9001:2000 |

| color | tansparent and translucent |

| Product Material | Rubber |

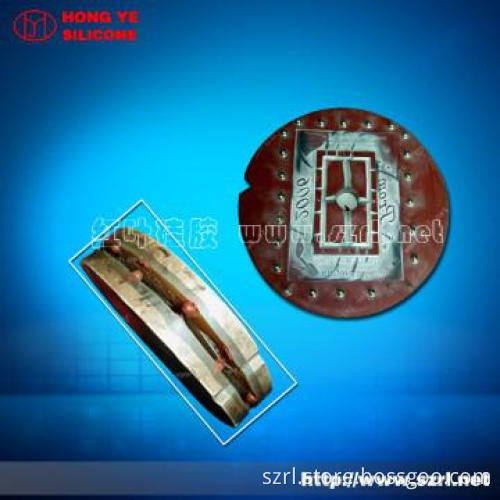

| Shaping Mode | Silicone Mould |

Detail Description

High Temperature Silicone for Jewelry Casting

Platinum Based Silicones For Jewelry Casting Description :

Platinum Based Silicones For Jewelry Casting are generally named as two-part addition silicone rubber that vulcanises at room temperature.Part A is a flowable liquid, part B is the curing agent(platinum catalyst). It features an exceptional fluidity ,good operability,excellent physical properties and very low shrinkage. The mixing ratio between Part A and Part B can be 10:1 or 1:1.

Platinum Based Silicones For Jewelry Casting Main application:

Rapid prototyping (urethane casting/silicone tooling/vacuum casting)

Concrete moulding

PU resin casting

General Mouldmaking

Superior manual mold designs

Cake/Chocolate molds

Platinum Based Silicones For Jewelry Casting Main properties:

almost nil shrinkage

high chemical resistance to aggressive components of some types of resins

good tear strength (this feature ensures higher resistance to wearing and shearing)

high degree of precision in reproduction

high dimensional stability over time and non-deformability

high resistance to high temperatures and ageing (resit to -60-200°C)

excellent non-stick effect

environmental, odorless and nontoxic

Platinum Based Silicones For Jewelry Casting

(The mixing ratio of part A and part B can be adjusted to 1:1or 10:1)

Product |

E-615 |

E-620 |

E-625 |

E-630 |

E-642 |

Appearance |

Translucent |

Translucent |

Translucent |

Translucent |

Translucent |

Hardness(shore A) |

15±2 |

20±2 |

25±2 |

30±2 |

42±2 |

Mix ratio(A:B) |

1:1 |

1:1 |

1:1 |

1:1 |

10:1 |

Viscocity Part A(mPa.s) |

22000±2000 |

23000±2000 |

27000±2000 |

25000±2000 |

55000±2000 |

Viscocity Part B(mPa.s) |

1900±500 |

1900±500 |

1800±500 |

2400±500 |

150±50 |

Tensile strength (MPa) |

5.2 |

5.7 |

6.7 |

5.5 |

7.6 |

Tear-strength (kN/m) |

25 |

26 |

23 |

24 |

22 |

Elongation(%) |

569 |

581 |

480 |

410 |

450 |

Density |

1.05 |

1.05 |

1.07 |

1.13 |

1.14 |

Pot life/working time (mins) |

30-40 |

30-40 |

30-40 |

30-40 |

30-40 |

Curing time/setting time (hrs) |

3-4hrs(25°C) 120-30mins(60°C) |

3-4hrs(25°C) 120-30mins(60°C) |

3-4hrs(25°C) 120-30mins(60°C) |

3-4hrs(25°C) 20-30mins(60°C) |

6-8hrs(25°C) 130-50mins(60°C) |

Shrinkage rate (%) |

0.1 |

0.1 |

0.1 |

0.1 |

0.1 |

Notice of Platinum Based Silicones For Jewelry Casting

All above addition silicone is forbidden to mix with organic compounds of condensation cure silicone rubber,otherwise, the silicone rubber will not cure, and also should not mix with organic compounds containing S, P, N as well as metallic salt of organic acids. It also will cause this product cure uncompletely or not cure.

Need any help on silicone rubber, please feel free to contact Ms Kitty:

Tel:86-755-89948294

Mob:86-15989267535

E-mail: hysh(at)szrl(dot)net

Skype:Kity-467707861

Additional Information

| Payment Terms | L/C, T/T |

|---|---|

| Minimum Order | 200kg |

| Lead Time / Delivery Time | 3 Day(s) |

| Sample Available | YES |

| Delivery Details | Within five days after getting your payment |

| FOB Port | Shenzhen |

| Loading Info | shenzhen port by sea |

| Packing Info | 20kg and 200kg per drum High Temperature Silicone for Jewelry Casting |

| Target Market(s) | North America, Oceania, Southeast Asia, Eastern Europe, Africa(except Middle East), Hong Kong/ Macao/ Taiwan, Latin America, Japan & Korea, Middle East & South Asia, Mainland China, Western & Southern Europe, Northern Europe, Central & Southern Asia, Middle East |

Related Keywords