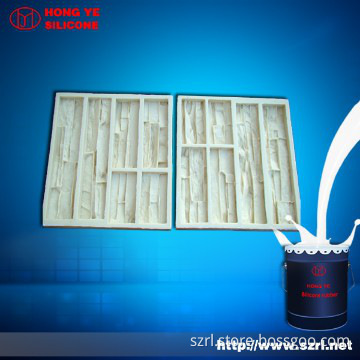

Liquid RTV Silicone Resin For Mold Making,rtv silicone,silicone moulds

Your message must be between 20 to 2000 characters

Contact NowBasic Specification

| Eco-Friendly | Yes |

|---|---|

| Test Report | SGS |

Detail Description

1.Application Of Liquid RTV Silicone Resin For Mold Making

A: Cultural relic duplication, architectural decoration, statues

B: Polyester Resin crafts

C: Lighting ornaments, soap, candles molding

D: Plaster, Gypsum, Cement, Concrete decorations

F: Model design, product exploitation, etc.

2.Description of Liquid RTV Silicone Resin For Mold Making

RTV2 mold making silicone for pouring is generally named as two-part room temperature sulfurated silicone rubber, which features an exceptional fluidity and good operability. When mixed with 2-3% curing agent, they can still be operated within 30 minutes, but will be formed after 2-3 hours. With resistance to deformation, high temperature, acid and alkali, and expansion, silicon flexible molds are used for mold duplication and delicate mold making for poli crafts, resin crafts lighting and candle crafts.

3.Features of Liquid RTV Silicone Resin For Mold Making

(1)high tensile & tear strength

(2) Low linear shrinkage

(3)free Curing agent

(4)brushing & pouring

(5) high duplication times

4.Operation instructions of Liquid RTV Silicone Resin For Mold Making

Correct mixing ratio

Component A is silicone rubber, and component B is curing agent or vulcanizing agent. Usually the mixing ratio will be 2-3%, e.g. to 100g silicone rubber should be added 2g catalyst and then mix them thoroughly. (Note: the weight of the silicone and catalyst should be weighed correctly).

Pouring the mixture and curing

Pour the misxed Part A base silicone and CA-30 curing agent as soon as possible onto the original,avoiding air entrapment.The catalyzed material will cure to a flexible rubber within 6 hours(or faster by different mixing ratio or room temperature),we advice you de-mold after 24 hours ,it is will improve the replicate times of silicone mold.

deterioration.

5.Datasheet of Liquid RTV Silicone Resin For Mold Making

| Item No | Appearance | Hardness (A°) | Viscosity (CS) | Tensile-strength( kgf /cm2 ) | Tear-strength (kgf /cm2 ) | Elongation-break(%) | Mixing Ratio of silicone and catalyst | Operating time (mins 25 0C ) | Curing time(hours 25 0C) | Application(most for resin, gypsum and cement product to make moulds) |

| 615# | White | 15±2 | 10000±2000 | ≥25 | ≥15 | ≥400 | 100:3 | 30-45 | 6-8 | Most suitable for small sized product by pouring method |

| 620# | White | 20±2 | 16000±2000 | ≥36 | ≥25 | ≥450 | 100:3 | 30-45 | 6-8 | Most suitable for small sized product by pouring method |

| 625# | White | 25±2 | 18000±2000 | ≥41 | ≥27 | ≥458 | 100:3 | 30-45 | 6-8 | Most suitable for small and medium sized product by pouring method |

Additional Information

| Payment Terms | L/C, T/T, Western Union |

|---|---|

| Minimum Order | 200 |

| Lead Time / Delivery Time | 3 Day(s) |

| Sample Available | YES |

| Delivery Details | within 3 days after payment confirmed in our bank. |

| FOB Port | Shenzhen, |

| Loading Info | by sea or by air |

| Packing Info | 5kg/drum 25kg/drum and 200kg/drum |

| Target Market(s) | North America, Oceania, Southeast Asia, Eastern Europe, Africa(except Middle East), Hong Kong/ Macao/ Taiwan, Latin America, Japan & Korea, Middle East & South Asia, Mainland China, Western & Southern Europe, Northern Europe, Central & Southern Asia, Middle East |

Related Keywords