plaster statues mold making silicone platinum,rtv silicone

Your message must be between 20 to 2000 characters

Contact NowBasic Specification

| MOQ | 200kg |

|---|---|

| validity | 1 year |

| color | any |

| appearanq | liquid silicone |

| Application | Silicone RTV2 |

| Eco-Friendly | Yes |

| Test Report | SGS |

Detail Description

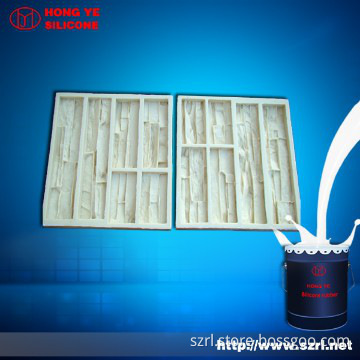

plaster statues mold making silicone platinum

Description of plaster statues mold making silicone platinum

plaster statues mold making silicone platinum is generally named two-components silicone

rubber, Part A and part B. It features an exceptional fluidity and good operability.

The mixing ratio is 1:1 (10:1),mainly be suitable for making molds application.

Typical Applications of plaster statues mold making silicone platinum

plaster statues mold making silicone platinum could be mainly used for making concrete

stones, wax molds, PU molds, resin molds, gypsum casting, candle molding and

chocolate , candy and any other FDA food product mold making, prototyping etc.

Characteristics of plaster statues mold making silicone platinum

*low shrinkage (less than 0.1% )

*high tensile and tear strength with high copy times

*easy for operation (mixing ratio at 1:1 /10:1)

*very good flow and easy for pouring operation

*Fast and non-shrink cure at room temperature which can be accelerated considerably by the application of heat

Technical propeties of plaster statues mold making silicone platinum

Model |

E625 |

Appearance |

Translucent |

Mixing Ratio |

1:1 or 10:1 |

Viscosity part A (Mpa.s) |

20000±2000 |

Viscosity part B (Mpa.s) |

3500±1000 |

Viscosity mixed(Mpa.s) |

7000 ±2000 |

Operating time ( Mins 25C) |

20-40mins |

Curing time ( Hrs 25C) |

2~5hrs |

Hardness (A°) |

25±2 |

Tensile-strength(kgf /cm2 ) |

60±5 |

Tear-strength (Kgf/cm ) |

23±2 |

Elongation-break(%) |

300±20 |

Retractility(%) |

≤0.1 |

(Please note: the above data for this product in 25°C temperature, 55percent humidity conditions, for reference. The accurate data is measured by customers when using.)

OPERRATING INSTRUCTION for plaster statues mold making silicone platinum:

1.Stir part A and part B with right mixing ratio evenly. (E630# is 1:1) and get the mixture for vacuum-pumping.(If there is no vacuumizer,you can just pour the mixture slowly from the corner so that less bubbles caused).

2.Enclose the product (the original model) with four plastic plates or wooden plates.

3. Clean your products and brush a layer of release agent(detergent or soap water) on your product.

4.Pour the mixture with correct mixing ratio into the model frame.

After about 2-4 hours, when the silicone cured, get out the original model, and there you get a finished addition cured silicone mold .

SHELF LIFE of plaster statues mold making silicone platinum:

Twelve (12) months from date of shipment when stored at 24°C in original unopened packages.

PACKAGE for plaster statues mold making silicone platinum:

Packed in clean 25kg/pail, 200kg/pail.

Need any help on silicone rubber, please feel free to contact Ms Maggie:

Tel:86-755-89212369

Mob:86-13828847574

E-mail: maggie822014(at)gmail(dot)com

Skype:maggie.cao82

Additional Information

| Payment Terms | L/C, T/T, Western Union |

|---|---|

| Minimum Order | 200kg |

| Lead Time / Delivery Time | 6 Day(s) |

| Sample Available | YES |

| Delivery Details | within 3 days after getting payment |

| FOB Port | Shenzhen |

| Loading Info | By ship or air |

| Packing Info | 25kg/drum and 200kg/drum |

| Target Market(s) | North America, Oceania, Southeast Asia, Eastern Europe, Africa(except Middle East), Hong Kong/ Macao/ Taiwan, Latin America, Japan & Korea, Middle East & South Asia, Mainland China, Western & Southern Europe, Northern Europe, Central & Southern Asia, Middle East |

Related Keywords