Silicone primer for silicone rubber insulator

-

USD28.1≥5 Kilogram

- Payment Type:

- T/T

- Min. Order:

- 5 Kilogram

- Min. Order:

- 5 Kilogram

- Delivery Time:

- 5 Days

- Transportation:

- Air

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 100000TONS /Month |

| Supply Ability: | 100000TONS /Month |

| Payment Type: | T/T |

| Certificate: | ISO9001 |

| Transportation: | Air |

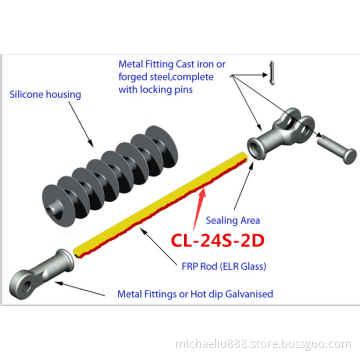

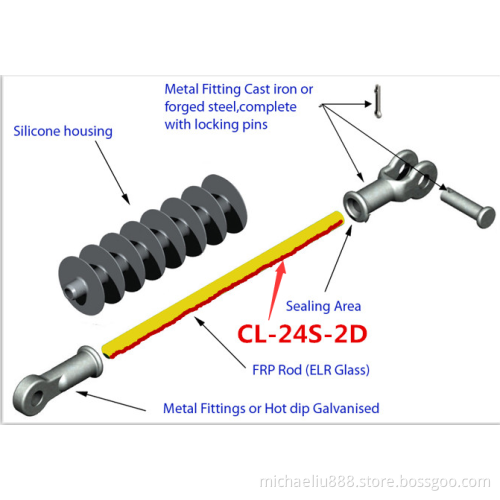

Silicone Primer CL-24S-2D

(Silicone to Epoxy Bonding)

Products Description

CL-24S-2D, one component silicone primer for Peroxide addition uncured silicone rubber bonds with Epoxy, Carbon metal,such as carbon stainless steel, aluminum, copper, Zn plating and nickle plating materials with excellent adhesion after curing.

Features

l Excellent adhesion for both once curing and second curing peroxide silicone rubber.

l One component, single coating, simple process.

l Resistance for many kind severe rugged environment, such as water resistance, salt fog resistance, chemical resistance, oil resistance, and solvent resistance etc...

Processing

1. Surface treatment: Cleaning the raw material with blast sanding, polishing or washed

by industrial alcohol.

2. Primering on: Brush, dipping or spraying.

3. Curing condition: Curing at 25℃ room temperature for at least 30 minutes or baking at 110~130℃ for 5-15 minutes.

4. After treatment: The treated substrates should be better to bond a.s.a.p. The max. Storage time can not be exceed 5 days under pollution- free environment.

5. Vulcanizing: The first curing is based on the silicone rubber`s curing condition, the second curing condition can not exceed 200℃.

Attention

l To be kept at cool and dry place, far away from the heat and open flame.

l Please cap its own cover immediately after use to avoiding volatilization.

l Less contact with skin and less inhalation ,make sure processing in one ventilation and fire protection area.

l Lightly cloudy of the primer won't affect the performance.

Packing

1000ml/bottle, 3kg/bottle

Related Keywords