30 Layers 24x36 Tacky Flooring Clean Room Facility Sticky Mat

Your message must be between 20 to 2000 characters

Contact Now30 Layers 24x36 Tacky Flooring Clean Room Facility Sticky Mat

1.30 layers per sticky mat

2.blue/white color

3.size:18x36/24x36/26x45

4.customer size available

| Type: | cleanroom floor mat |

|---|---|

| color: | white/blue |

| size: | 24"x36" |

| ply: | 30 layers |

| thickness: | 1.1-2.0mm |

- Adhesive layered, straight edged mats can quickly, effectively remove traffic dirt from wheels and dust from the soles of shoes, to keep the clean environment

- Each sticky mat is composed of multiple layers of polyethylene film laminated together into a stack

- Each layer is coated with a unique high or low adhesive, and the working surface is smooth

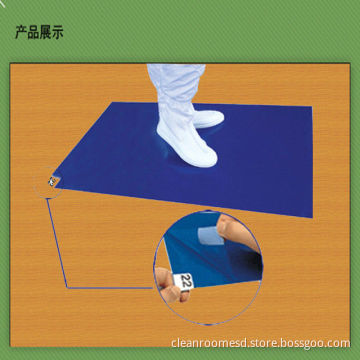

- Easy to use. When the surface layer is contaminated, simply peel off the top layer and throw it away

- Mainly used for electronics, computer, instrumentation, medical-device, pharmaceutical, aerospace and nuclear industries

|

Base Material |

Polyethlene film |

Size: |

|

Tab Size |

1" x 1", white |

|

|

Sticky Strength |

200~800g/25mm |

|

|

Adhesive |

Solvent-based acrylic |

|

|

Heat resistance |

70degree (24 hours) |

|

|

Thickness |

1.8 mm (mat) |

|

|

Color |

Blue, White |

|

|

Packaging |

10 mats/case, 30 layers/mat |

More Detailed Product Description Please Click here: Sticky Mats Spec.PDF

Clean Room Sticky Mats

Each mat is composed of multiple layers of polyethylene films; each layer is attached with high-viscosity or low-viscosity coating layer, smooth and durable. It can quickly and effectively remove contamination and dust from shoes and wheels. When the surface sheet becomes dirty, simply peel it off and use the next layer.

Technical datasheet:

|

NO. |

Test items |

Testing standards |

Test results |

|

1 |

Longitudinal Tensile strength(MPA) |

≥10 |

20 |

|

2 |

Transverse Tensile strength(MPA) |

≥8 |

17 |

|

3 |

Longitudinal Elongation(%) |

≥150 |

210 |

|

4 |

Transverse Elongation(%) |

≥200 |

255 |

|

5 |

Film Thickness |

0.04MM ±0.005 |

0.039mm |

|

6 |

Original Tackiness(G/IN2) |

LOOPTACK |

400 |

|

7 |

180 Temperature Peeling Strength(SS.G/25MM) |

GB2792-81 |

380 |

|

8 |

Support viscous(MIN) |

GB4851-98 |

1440 |

|

9 |

High temperature high humidity test |

Q/DT1-2004 |

80DegreesCelsius |

|

10 |

Heat experiment |

Q/DT1-2004 |

-- |

|

11 |

Aging |

Q/DT1-2004 |

Eight Months |

|

Film Material |

Low density polyethylene |

||

|

Layers per Mat |

30 Layers/Mat |

||

|

Adhesive Material |

Water-based acrylic |

||

|

Size |

18”× 36”, 24”× 36”, 26”× 45” |

||

|

Color |

Blue |

||

|

Storage Condition |

Temperature: 40C~450C, Humidity: 25%~70% |

||

|

Package |

8 or 10 mats/carton |

||

Applications:

Mainly used for electronics, computer, instrument, medical- device, pharmaceutical, aerospace,cleanroom and nuclear industries