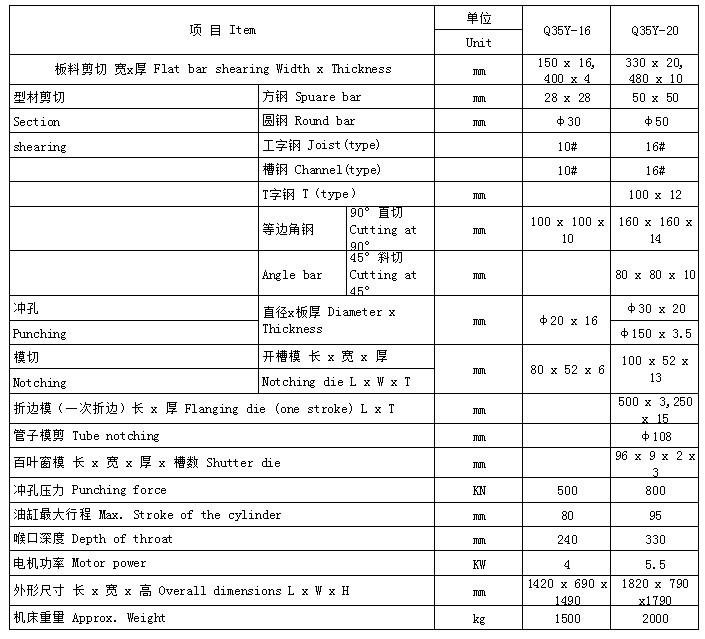

High Speed And High Precision Numerical Control Hydraulic Joint Sheet Metal Shear, Q35y-16

Your message must be between 20 to 2000 characters

Contact Now

High Speed And High Precision Numerical Control Hydraulic Joint Sheet Metal Shear, Q35Y-16

Tip: punch; punch press; sheet metal shear; sheet metal shears; sheet metal cutters

Explanation:

This machine is of numerical control hydraulic ascendant type bending machine, their safety and operation, practicability are superior to the previous model, and have excellent mechanical precision.

1. on the wedge, the fixed way, and the overall frame welding compared, won't produce skewed and go around the song, can guarantee the long time use all has a high precision.

2, hydraulic main cylinder into the machines installed the axis of the focuser drawtube department, the way the central pressure, prevent were broken workpiece insufficient central force, and at the same time, pressure and produced when mesa skewed sent suppressed in the least limit, so the precise products processing.

3, the dynamic way under the rise, molding, will drive are hiding in the lower part of the machine, make all the space between frame, for larger panel is also simple to carry on the processing.

4, either in the movement of the front and back, the or so direction are supplied the wheel steering mechanism so that the workbench is very smooth movement, and can adjust the wheel and guide a gap, the up and down between the mesa parallel degree will keep right.

5, the D axis control of the upper limit of the set, can determine the high precision bending depth, can to the product's flex Angle adjustment of no stage.

6, in order to improve the operation efficiency, with the lower limit control device, and set limit to work with simple agency best stroke.

7, with the rising velocity switching device, in bending small workpiece as speed switch points in their proper location choice, in order to avoid extra spare travel.

8, the rate of movement of the next table according to trample feet would increase or decrease of the stem any control, or among do stop, that should be crossed the operation of easy with; Secondly, the down to stem after let go, the lower mesa back to the original immediately stop position, so is high security machinery.

9, the L axis and R axis control of high speed and high precision workpiece bending after automatic positioning device, the beams and block material after stent is using aluminum production, moving parts and using the straight-line bearing with linear guide rail, with light and beautiful, high precision, high load capacity, high rigidity, high reliability, sports, low noise, smooth the seal of the dust high quality characteristics.

10, and the use of segmentation moulds, a person can also convenient mould replacement, equipped with the rapid clamping middle board, installation is simple, and can prevent the upper die off, to adopt the automatic core structure, fine scale, Angle adjustment is simple and accurate.

11, from Japan mitsubishi is the latest numerical control system, and touch input, have Angle input and direct input mode, can greatly improve the accuracy and productivity products.

12, with the use of high quality import sealing and famous brand hydraulic pump, electromagnetic reversing valves, electric components. Ensure the reliability of the machine.

Q35Y-16 Numerical control Hydraulic joint sheet metal shears

Related Keywords