silicone bra adhesive liquid silicone adhesive

- Payment Type:

- T/T, L/C, D/A, D/P, Western Union, cash

- Incoterm:

- FOB

- Min. Order:

- 5 Kilogram

- Min. Order:

- 5 Kilogram

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 5000tons |

| Supply Ability: | 1000000000000 |

| Payment Type: | T/T,L/C,D/A,D/P,Western Union,cash |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

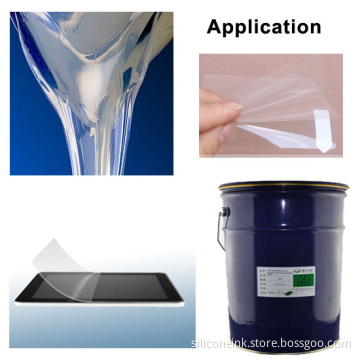

Silicone Adhesive/Glue for silicone Brassiere

KL-6634A/B

KL-6634A/B is two components compound. Self-adhesive and pressure-sensitive. Transparent silicone base adhesive/ glue for silicone Bra (Brassiere). Heat and fast cured type adhesive for silicone, TPU and so on.

The silicone adhesives are characterized by high performance of surface Stripping Resistance, good levelling property, electrical insulating property, high grade of transparency and easy to clean with water.

Mainly used for silicone Bra, silicone massage pad, pads and other silicone products.Can touch the skin and reuse cyclically.

Physical Properties:

Appearance: A: Clear colloid B: Clear colloid

Hardness: 3.5°A

Viscosity: 50000mpa.s

Solid Content: 90%

Curing Condition: TC10:19S*120℃

TC90:50S*130℃

Tensile Strength: 0.71Mpa

Elongation at Break: 300%

Tear Resistance: 1.07KN/m²

Surface Stripping (Resistance at 180℃): 60±1g/25mm (ASTM D333)

Light Transmittance: 90%

Application ratio: A: B=1: 1 (Weight)

Application Method:

1. Mixing uniformity A and B by a ratio of 1: 1.

2. Coating uniformity of silicone adhesive on the substrate (silicone, EVA, clothe, PET or other material) by coating method or rolling process.

3. Give temperature. Baking at 90℃ for 540seconds.

Note:

1. The application ratio should be adjusted appropriate to different materials, the thickness of coating and weather conditions (temperature and humidness). The application ratio should better increase 5%~10% based raw ratio at hot and humid conditions.

2. Cleaning base materials and keep it dry, free of dust and oil.

3. Controlling and checking the viscosity during the coating process. Pay attention to the quantity for once and make it deeply cured.

4. The operating environment is important for coating process, please work in dust-free plant at constant temperature 25-35℃ and constant humidity at 15-60%. During the operating process, more dust pollution more NG products, as the changing of temperature and humidity, bad property of flowability and adhesion strength will be appeared by low temperature, and, the higher humidity will cause coating shrinkage cavity, the lower humidity will cause potential safety hazard and whity by static.

5. The mixed silicone adhesive should be used up within 1 hour, if high viscosity happens, stop coating at once.

6. The work shop should be ventilated and workers should wear labour protection tools during the coating process. Away from open flame, high temperature and pay attention to static electricity.

7. Please read the product safety instructions before using.

Storage: Stored at room temperature for 6 months without mixing.

Packing: 20KG/Barrel.50KG/Barrel

Related Keywords