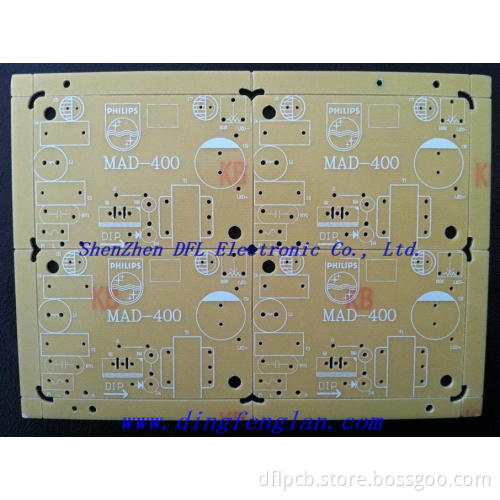

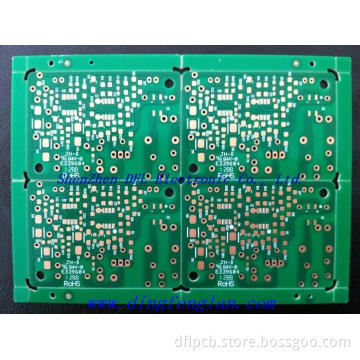

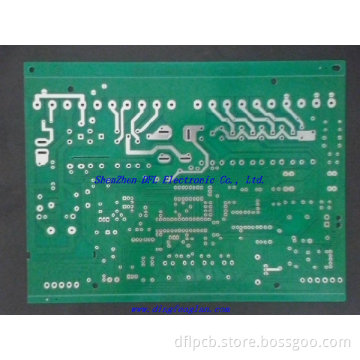

Philips CEM-1 Single-Sided PCB

- Min. Order:

- 1

- Min. Order:

- 1

- Delivery Time:

- 7 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | ShenZhen,China |

|---|---|

| Certificate: | UL |

Product Description

Product Description

Philips CEM-1 Single-Sided PCB:

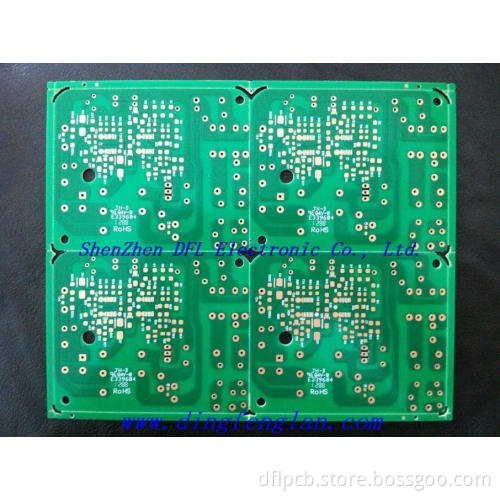

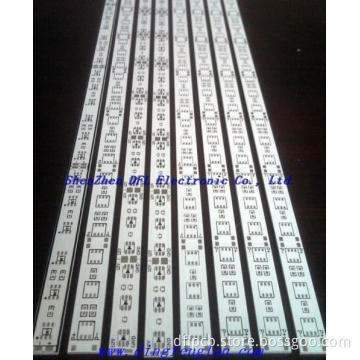

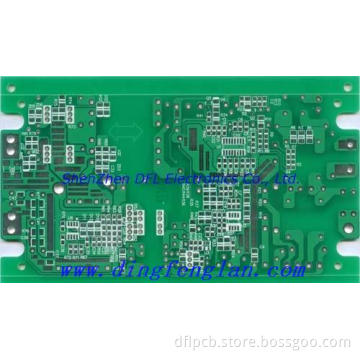

Layer count: Single layer

Base material: 1.6mm CEM-1

Finished copper weight: 1oz

Surface finishing: OSP

Solder mask: Green

Board size:Customized according to the supplied gerber file

DFL is able to offer one stop 1 to 4 Layer PCB fabrication,PCB manufacturing,Reverse engineering service,FPC fabrication, Aluminium base fabrication

Our PCB board manufacture

* PCB board made, circuit board parts purchased by us

* Electronic testing circuit board

* Fast delivery, vacuum package

* RoHS Directive-compliant, lead-free

PCB Capabilities:

Material: 94 HB , 94 V0 , FR - 4 ,CEM - 1 ,22F,Aluminum base ,Copper base

Surface Finish: HASL,Lead - free HASL,Electronickelling,Electrogilding,OSP ect

Maximum Panel Size: 1200 mm * 450mm

Minimum Thickness: 0.30mm

Minimum Line Width:0.10mm

Minimum Hole Diameter: 0.30mm

Hole Dia.Tolerance: 0.10mm

Insulation Resistance: >1014

Electric Strength: 1.3Kv/mm

Peel Strength:1.4N/mm

Thermal Shock: 288degree 10sec

Fire Retardant: 94 V-0

Thickness of The Copper Foil: 1/2oz,1oz,2oz

Hardness of Solder Mask: >5H

Testing Procedures For PCB Board

---We perform multiple quality assuring procedures before shipping out any PCB board

These include:

Visual Inspection

E-test

Bed of nails

Impedance control

Solder-ability detection

Digital metallograghic microscope

AOI (Automated Optical Inspection)

Detailed Terms for PCB Manufacturing

---Technical requirement for pcb assembly:

* Professional Surface-mounting and Through-hole soldering Technology

* ICT(In Circuit Test),FCT(Functional Circuit Test) technology

* PCB With UL,CE,FCC,Rohs Approval

Delivery Time for PCB board

PCB production time: sample: 3-4 days / mass production: within 7 days

Quotation Requirement and Time:

1) Following specifications are needed for quotation:

a) Base material:

b) Board thickness:

c) Copper thickness:

d) Surface treatment:

e) Color of solder mask and silkscreen:

f) Quantity

Layer count: Single layer

Base material: 1.6mm CEM-1

Finished copper weight: 1oz

Surface finishing: OSP

Solder mask: Green

Board size:Customized according to the supplied gerber file

DFL is able to offer one stop 1 to 4 Layer PCB fabrication,PCB manufacturing,Reverse engineering service,FPC fabrication, Aluminium base fabrication

Our PCB board manufacture

* PCB board made, circuit board parts purchased by us

* Electronic testing circuit board

* Fast delivery, vacuum package

* RoHS Directive-compliant, lead-free

PCB Capabilities:

Material: 94 HB , 94 V0 , FR - 4 ,CEM - 1 ,22F,Aluminum base ,Copper base

Surface Finish: HASL,Lead - free HASL,Electronickelling,Electrogilding,OSP ect

Maximum Panel Size: 1200 mm * 450mm

Minimum Thickness: 0.30mm

Minimum Line Width:0.10mm

Minimum Hole Diameter: 0.30mm

Hole Dia.Tolerance: 0.10mm

Insulation Resistance: >1014

Electric Strength: 1.3Kv/mm

Peel Strength:1.4N/mm

Thermal Shock: 288degree 10sec

Fire Retardant: 94 V-0

Thickness of The Copper Foil: 1/2oz,1oz,2oz

Hardness of Solder Mask: >5H

Testing Procedures For PCB Board

---We perform multiple quality assuring procedures before shipping out any PCB board

These include:

Visual Inspection

E-test

Bed of nails

Impedance control

Solder-ability detection

Digital metallograghic microscope

AOI (Automated Optical Inspection)

Detailed Terms for PCB Manufacturing

---Technical requirement for pcb assembly:

* Professional Surface-mounting and Through-hole soldering Technology

* ICT(In Circuit Test),FCT(Functional Circuit Test) technology

* PCB With UL,CE,FCC,Rohs Approval

Delivery Time for PCB board

PCB production time: sample: 3-4 days / mass production: within 7 days

Quotation Requirement and Time:

1) Following specifications are needed for quotation:

a) Base material:

b) Board thickness:

c) Copper thickness:

d) Surface treatment:

e) Color of solder mask and silkscreen:

f) Quantity